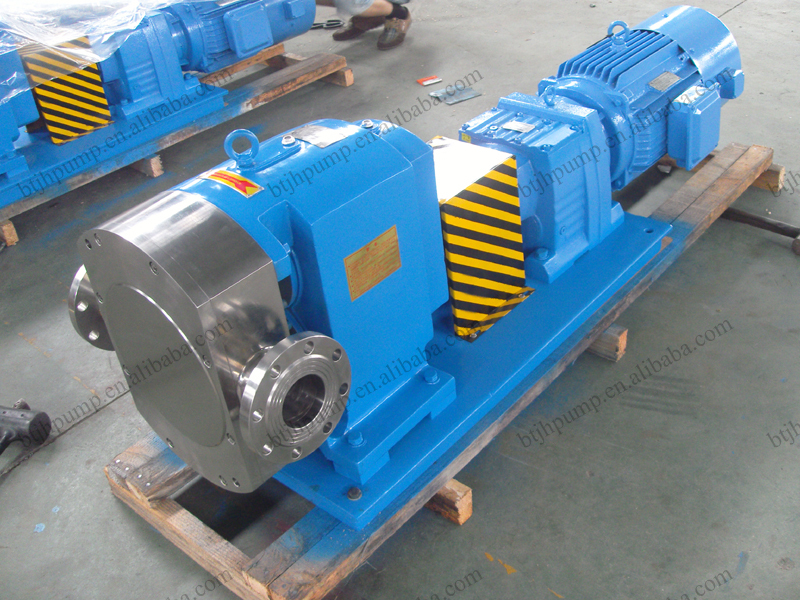

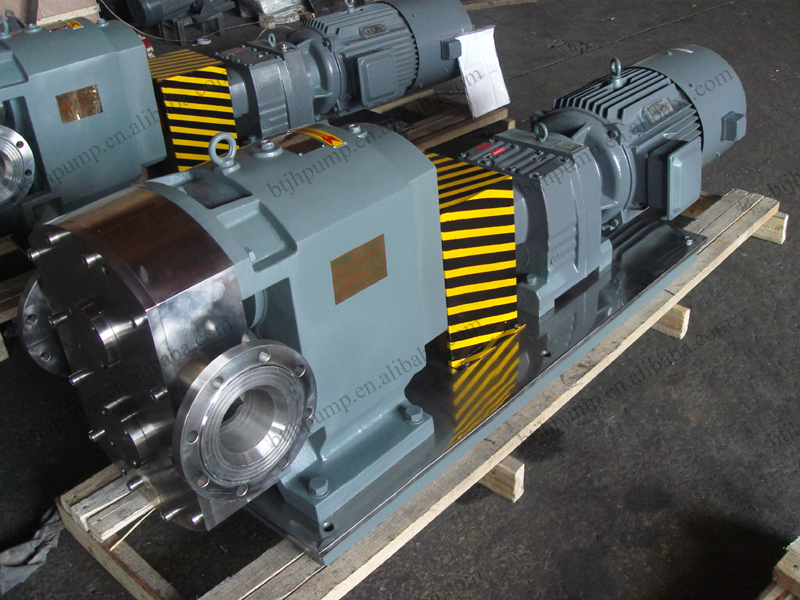

The rotary pumps are multi-functional and bi-directional pumps. They are manufactured after years of research and with advanced technologies.

The products use two synchronic rotors, the rotors are driven by a pair of outer-set synchronic gear boxes and the transmission shaft. They move

synchronically in counter-clockwise directions. Consequently, builds up high vacuum capacity and emission pressure. It is particularly suitable for

the pumping of pharmaceutical grade, high-corrosive and high-viscous materials.

The product is classified into sub-standard medical grade, corrosion-resistant, sludge three series; the structure of the high-pressure high-viscosity,

high-pressure and low viscosity two categories; ordinary type, food grade, chemical and oil based, special five series according to the different

characteristics of different media, using different materials and different forms enclosed manufacturing, and materials to meet the characteristics of

different media, using different materials and different formsenclosed manufacturing and materials to meet the various needs of the production process

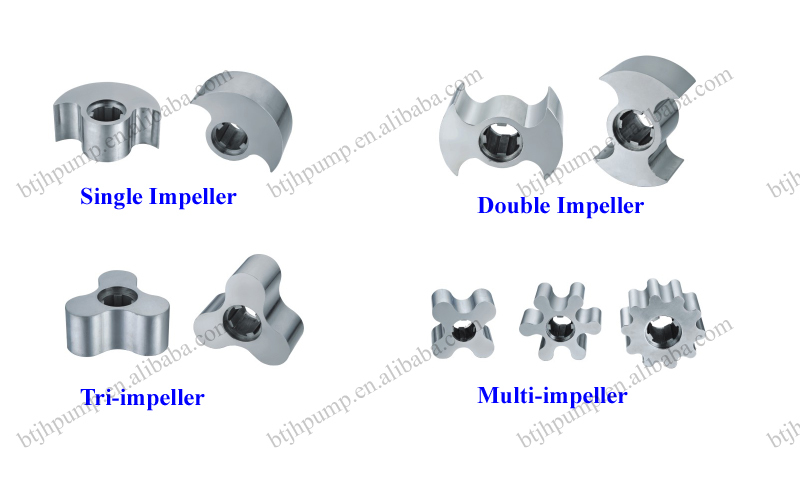

to improve the delivery of professional products. Our motor design has 12 varieties and each rotor can be used interchangeably on the same pump.

1. The pharmaceutical pumps are made of stainless steel 316, in full compliance with the GMP requirements of FDA.

2. Corrosive-resistant pumps are made of corrosive-resistant stainless steel and high-polymer reinforced materials.

3. Sludge pump make breakthrough not only in structure, but also in the use of special wear-resistant materials. They are very helpful to the

wear-resistance of the pumps and the transmission of slush.

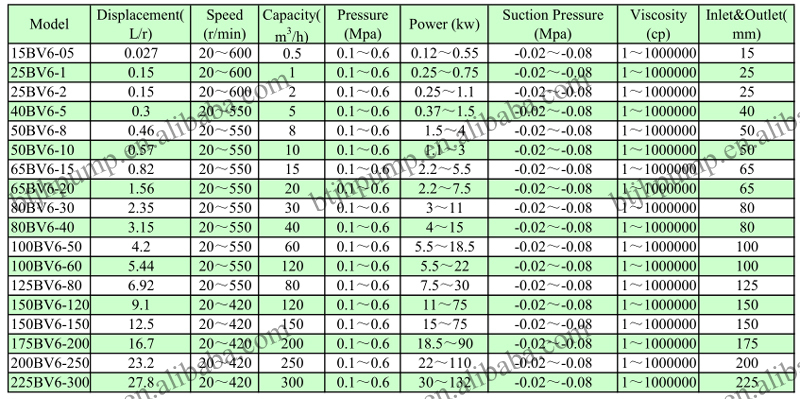

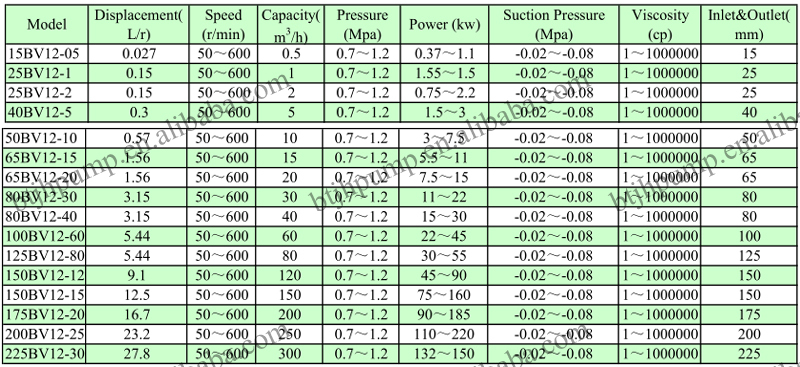

Technical Data

Advantages of Rotary Pump

Ø Gap is kept between the rotors and between the pump body. No friction, long life.

Ø Simple installation and disassembling. Easy maintenance and cleaning. Strong resistance to wearing.

Ø High efficiency and energy-saving. Low failure, reliable sealing and low noise.

Ø Special materials are used to pump medium with solid granules. Like sludge and sewage.

Ø Capable to pump the viscous material below 2 million cp and pulp with the solid volume of 70%.

Ø Equipped with frequency converter, flow can be adjusted at will and can be used as general measurement pump.

Ø Flange, screw or coupling interfaces can be used as required by the customer.

Ø Capable of pumping mixtures of gas, fluid and solid materials.

Ø Thermal insulation and cooling pump is of a built-in structures with high heat conductivity.

Ø Movable pumps can be used to pump canned fluids medium, with intake vacuum level -0.02Mpa ~-0.095Mpa

Ø Hygienic safety Valve can be set at the pump head if customer required.

Application of Rotary Pump

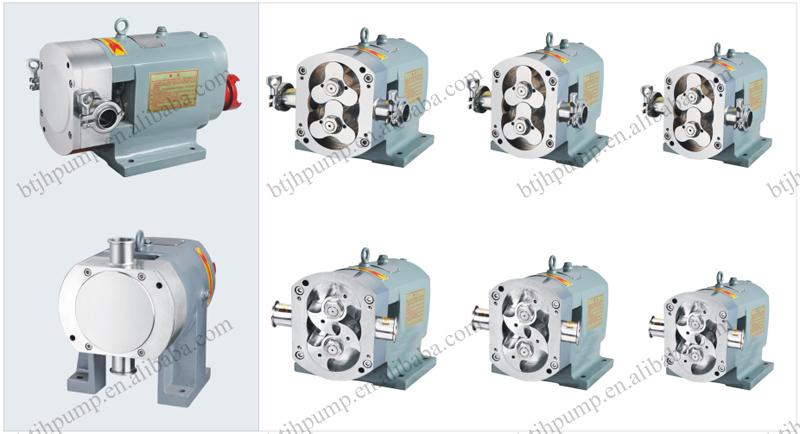

Structure Map of Rotary Pump

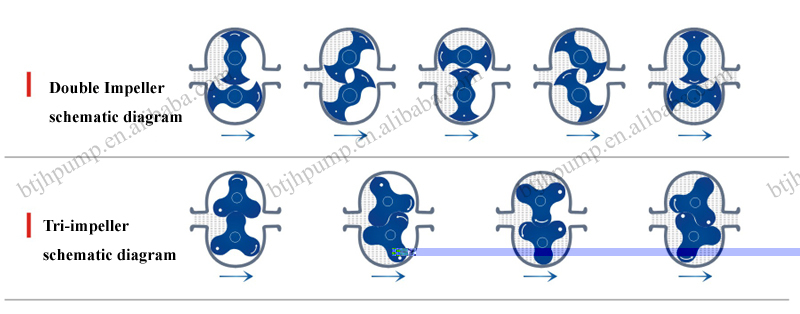

Schematic Diagram of Rotary Pump

Classification of Rotor of Rotary pump

High-precision Processing Equipment Display

_60073882822.html?spm=a2747.manage.list.49.vOg2Yf

_60073882822.html?spm=a2747.manage.list.49.vOg2Yf

Transportation

Contact us if you need more details on Food Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rotor Pump of Stainless Steel、Rotor Pump of Stainless Steel. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Rotary Pump